Description

They have been a long time coming, now they're here!

New AAD Performance Sway Bar Endlinks W/Spheriflex for your modern Mopar! Our original design provides all of the performance of steel heims with none of the noise, for unparalleled durability! Our endlinks are turned out of 1-5/8" 6061-T6511 aluminum billet, with the bearing races bored into the parts, the rebuildable Spheriflex bearings are installed in both ends of the links.

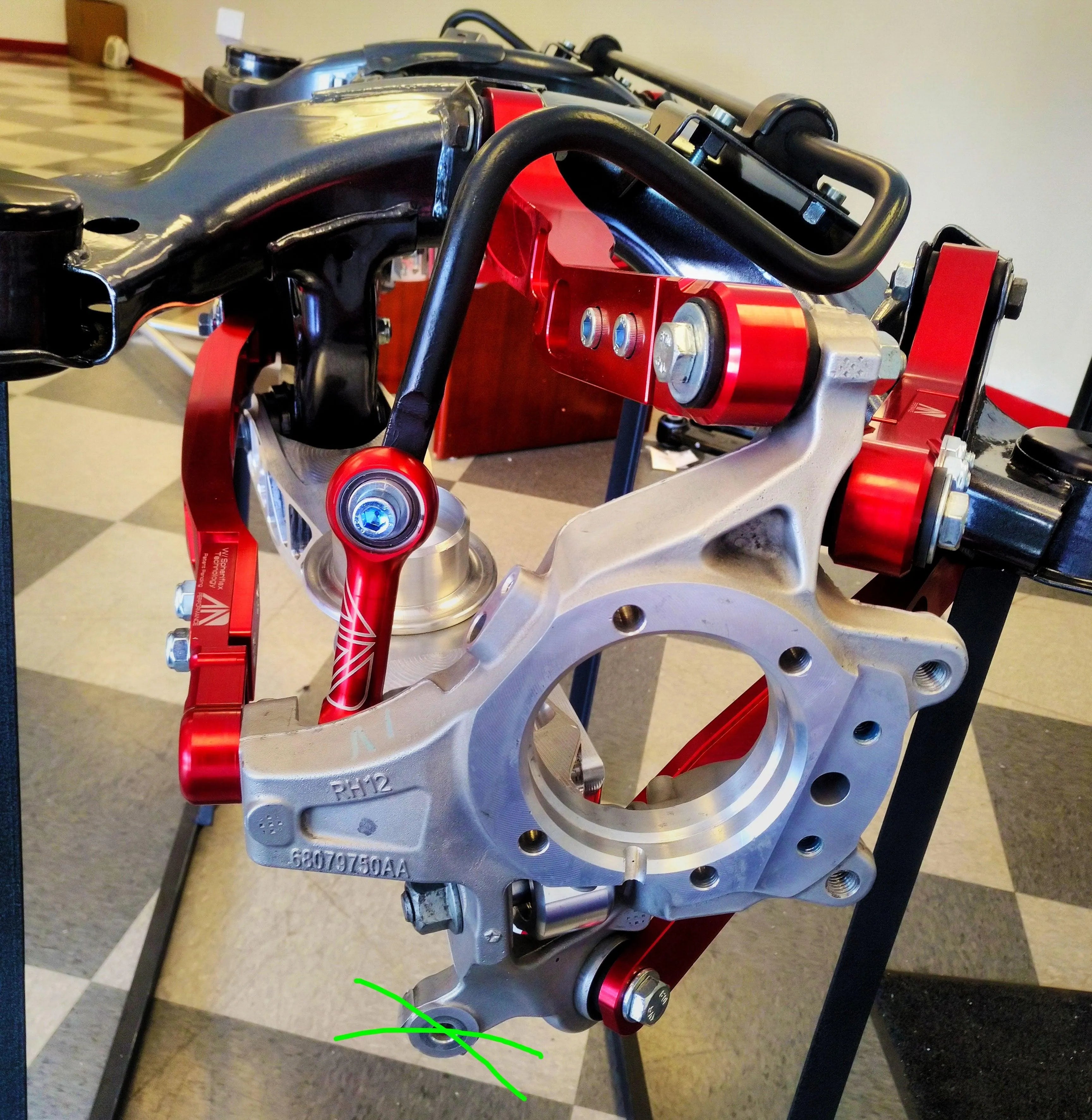

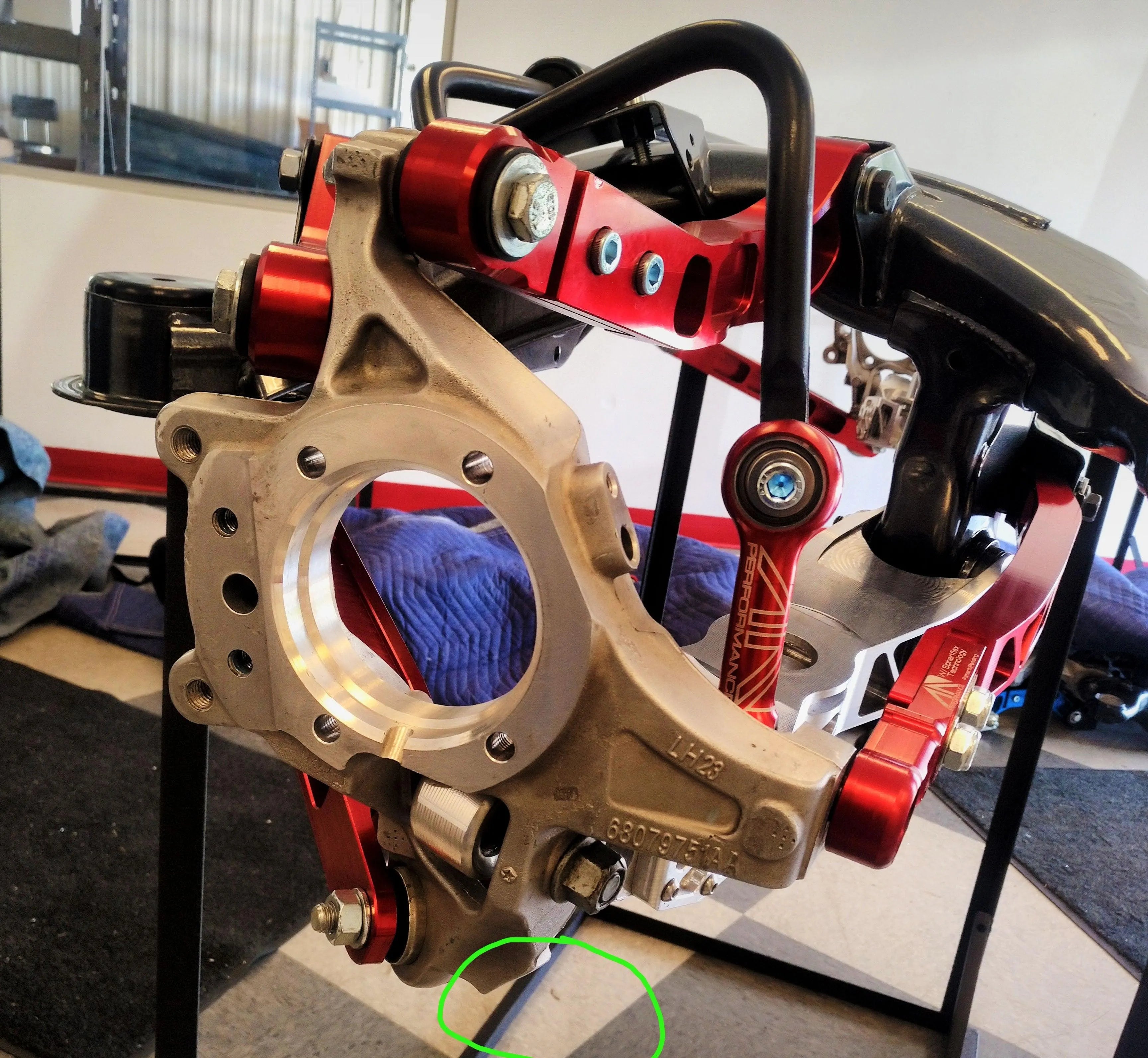

Designed to work with our revolutionary Toe Links, our new Exclusive Rear Endlink geometry moves the mounting point for the rear endlinks from the ear that sticks down below the knuckle and interferes with 15" wheels, and moves it to the backside of the toe link, replacing the nut. You can then remove that ear if you wish to clear smaller wheels!

Designed to provide unparalleled performance and durability, our new Front Endlinks match our Rear Endlinks and look great while enhancing your cornering abilities!

Our Spheriflex design allows us to make the Spherical bearing ball the actual nut, allowing us to get 10 lbs of stuff into more compact, lighter 2 lb package! These rear endlinks have been designed to be the correct length to clear both our control arms, and 15" wheel barrels, taking the guesswork out of adjusting double-side-threaded endlinks with jam nuts.

Find the Front Endlinks by themselves, Here!

Find the Rear Endlinks by themselves, Here!

The first few dozen sets are going to be at a reduced price, these are going up soon!

Rear Endlink Installation Instructions:

Front Endlink Installation Instructions:

***Check wheel clearance before driving, we have tested with several different wheel manufacturers/models, but obviously can't check everything. We're not buying your wheels if they scuff because you didn't check clearance, please check after install with suspension NOT at full droop before driving. Thanks!!!!!***

***As best we know these should fit all applications, but there are many different rear knuckles over the years. Install is done by removing the toe link bolt, then screwing it in when the endlink side is against the knuckle, if you try to thread the endlink onto the bolt that is fully installed into the knuckle already, the endlink won't fit. Illustrated Instructions coming soon, we just got this first batch back from anodize today! If you encounter an application that seems to not fit, please take pictures of the interference and send to ParkerB@allanglesdesign.com and we will either solve your problem or send you a return label and refund.***